Prepainted metal roof offer

BackPrepainted metal roof offer

Paint systems for prepainted metal roofs

Polyester

Coatings based on polyester resins can be flexible, permitting them to withstand deformation processes, but can also be designed to be very hard and tough. They feature a balance of surface properties such as flexibility and scratch-resistance – while also being very economical. Polyesters can be used with smooth and textured surfaces.

Polyurethane

In this paint system polyurethane or polyester resins are used and cross-linked with isocyanates. This cross-linking results in better resistance, adhesion and flexibility compared with polyester coatings. However, these benefits also entail higher materials costs. Same as Polyesters, Polyurethanes can be used with smooth and textured surfaces.

Plastisol

Coatings based on PVC dispersions are standard materials for steel wall and roof elements. With a film thickness of 150 to 200 mm, they are extremely tough and durable, offering very good corrosion protection even in aggressive industrial atmospheres. More recent developments with good UV resistance are very durable even in extreme weather conditions.

PVDF

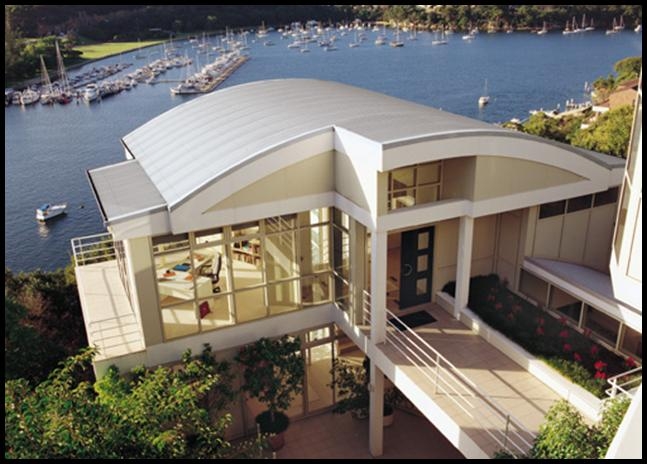

PVDF coatings, based on polyvinylidene fluoride resins, are absolutely ideal for long-term outdoor use. This happens thanks to their outstanding resistance to UV radiation and sunlight and their excellent deformability and corrosion resistance. PVDF coatings are mainly used on architecturally striking buildings.